Since 1986 A-One Textile & Towel Industries has specialized in Manufacturing & Exporting the best quality "Terry Products", in the form of "Bathrobes, Fancy Towel and Large Beach Towels, are appreciated THE WORLD OVER. The company is having 100 % in-house facility with fully dedicated Faculty and is spread over 200,000 Sq Feet of area & Having the Capacity of Exporting (2)two 40ft containers a day...

The management of our company has always high regards for the need and requirements of the valuable customers. The basic policy designed by the management was to cater the " Terry Towel Industry" in all and every aspect. However, the primary bussiness was to achieve a sustainable position in an Export Market.

Under the all circumstances, the management of the organization is keeping in view the requisite of the international market that the company has come to acquire the world wide clientele.

During the (more than 23 years) period, the company has become a considerable place in world export market and has either achieved, on which it can claim pride the satisfaction of its valued customers. The organization has added quite a few feathers to the achievement but the trust of the customers if the most precious and valuable asset. The Factory is

The company has been awarded by AITEX (Instituto Tecnologico Textil),

Being one of the leading manufacturer & exporters we are mainly shipping goods to the following countries.

M/S "A-ONE TEXTILE" takes pride to inform that we are Working across the globle with our reputed clients, and our

M/S "A-ONE TEXTILE" takes pride to inform that we are Working across the globle with our reputed clients, and our

2005________________19 MILLION U.S.D

2006________________21 MILLION U.S.D

2007________________25 MILLION U.S.D

2008________________27 MILLION U.S.D

2009________________30 MILLION U.S.D

2010________________32 MILLION U.S.D(EXPECTED)

"BUSSINESS WITH AN APPROACH"

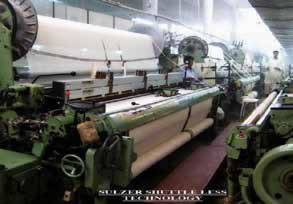

The Weaving:The company has brought latest "Shuttle less Weaving Lomms" Specialized Weaving:-The factory is also equipped TOTAL WEAVING LOOMS: 268 |

|

DYEING PROCESS:Through the well-organized dyeing processing set-up in our |

|

FABRIC SHEARING FACILITY:The company provides "Fabric Shearing (VELOUR) Facility" |

|

EMBROIDERY DEPARTMENT:Offering a complete manufacturing designs and process |

|

STITCHING DEPARTMENT:Factory is Equipped with 4(four) stitching floors working |

|

OFFICE AND SHOWROOM:Factory comrises of a healthy and professional office with |

|

LABORATORY:From the very inception, the company has placed |

|

QUALITY CONTROL:The company's management implements strict quality "Our Quality Becomes Benchmark For Others...." |

|